Secret Jardin DF16 Extractor T 150/250/350 m3/h UE/UK/US

GreenBroz 420 Alchemist Extractor

The 420 Alchemist solventless trichome extractor from GreenBroz is engineered to help you maximize your harvest. It can process up to 10 pounds of trim per cycle and generally yields 15%-25% of your trim’s weight in kief that can be sold as is or turned into a variety of product SKUs.

GreenBroz 215 Alchemist Extractor

The 215 Alchemist solventless trichome extractor from GreenBroz is engineered to help you maximize your harvest. It can process up to 2.5 lbs. of trim per cycle and generally yields 15%-25% of your trim’s weight in kief that can be sold as is or turned into a variety of product SKUs.

Zenoprt EC102. The Extraction Contraption Pro System harnesses the sub-zero temperatures of dry ice sublimation along with centrifugal force to produce plant essence in a fraction of the time of traditional processes. There is no water or harsh chemicals used during the extraction process. In fact, our process actually removes much of the plant’s natural moisture. The final essence is a fine, dry powder. The Extraction Contraption Pro System is constructed of high quality stainless steel, and has an optional compactor so you can process and package your plant extraction quickly and easily. Plant processing times vary. Hardy, small mass plants like pine can take up to 45 minutes. rosemary takes approximately 30 minutes, while lavender can be processed in about 10 to 15 minutes. The Extraction Contraption Pro System is 100% food grade and is ideal for edibles, medicines and other plant essence products meant for human consumption. It can also be used to produce lotions, soaps, scents and other non-edible plant essence products. NOTE: The mixer unit is sold separately and can be purchased at any Harbor Freight. Ask for Central Machinery – Item #91907.

2 lb Icarus True Dewax Closed Loop Extractor

The Icarus unit shares the same function of the standard Bi-directional extractors, but features rack mounting for ease of use. It is also the 2lb True Dewax unit. By utilizing an input manifold for the solvent, the user can switch from bottom flood to a top input on the material column. This method ensures that all material has been saturated and rinsed of oils on the first run. The oil-bearing solvent then dumps into a sleeved spool, where it is chilled with dry ice. Once the solvent has chilled, waxes and lipids will coagulate and fall out of the solution. The solution is then filtered and dumped into a collection base. The rack unit comes standard with a port for nitrogen assistance.

Features:

• Up to 2 lb material capacity

• Bi-directional solvent input

• Secondary dewaxing

• Solvent reclamation

• Splatter platter collection base for easy extract removal

• Sight glasses on collection base

• 100 micron filtration built into gasket

• Rack mounting

Benefits:

• Rack mounting to prevent heavy lifting

• Maximum oil yield

• Full dewaxing without second solvent

• Save money with solvent reclamation

• Nitrogen assist to prevent vapor lock

Includes:

• Extruded aluminum rack with pipe hangers

• 10” x 10” collection base

• #30 LP tank

• Solvent input manifold

• 4” x 24” material column

• 6” x 24” dewaxer with filter assembly

• Stainless steel braided PTFE hoses

• Buna-N tri-clamp gaskets

• High pressure clamps

ADDITIONAL EQUIPMENT REQUIRED FOR OPERATION OF UNIT. THIS UNIT REQUIRES A VACUUM PUMP, DRY ICE AND NITROGEN TANK WITH REGULATOR TO FUNCTION.

It is also recommended to have a refrigerant scale to operate this unit.

A VE280 9cfm 2 Stage (BVVVE280) vacuum pump is recommended for this system.

Technical Specs:

Max Allowable Working Pressure: 150 PSI

Operating Temperature Range: -40F – 200F

304 Stainless Steel Construction

High Polish Interior

Solvent Capacity: 10 lbs

5 lb Icarus True Dewax Closed Loop Extractor

The Icarus unit shares the same function of the standard Bi-directional extractors, but features rack mounting for ease of use. It is also the 5 lb True Dewax unit. By utilizing an input manifold for the solvent, the user can switch from bottom flood to a top input on the material column. This method ensures that all material has been saturated and rinsed of oils on the first run. The oil-bearing solvent then dumps into a sleeved spool, where it is chilled with dry ice. Once the solvent has chilled, waxes and lipids will coagulate and fall out of the solution. The solution is then filtered and dumped into a collection base. The rack unit comes standard with a port for nitrogen assistance.

Features:

• Up to 5 lb material capacity

• Bi-directional solvent input

• Secondary dewaxing

• Solvent reclamation

• Jacketed base for temperature control cicrulation

• Splatter platter collection base for easy extract removal

• Sight glasses on collection base

• 100 micron filtration built into gasket

• Rack mounting

• Premium SSP fully encapsulated ball valves

Benefits:

• Rack mounting to prevent heavy lifting

• Maximum oil yield

• Full dewaxing without second solvent

• Save money with solvent reclamation

• Nitrogen assist to prevent vapor lock

Includes:

• Extruded aluminum rack with pipe hangers

• 12” x 12” jacketed collection base

• #50 LP tank

• Solvent input manifold

• (2) 4” x 24” material column (4” x 48” Total)

• 6” x 36” dewaxer with filter assembly

• Stainless steel braided PTFE hoses

• Buna-N tri-clamp gaskets

• High pressure clamps

ADDITIONAL EQUIPMENT REQUIRED FOR OPERATION OF UNIT. THIS UNIT REQUIRES A VACUUM PUMP, DRY ICE, NITROGEN TANK WITH REGULATOR, AND HEATER CIRCULATOR TO FUNCTION.

It is also recommended to have a refrigerant scale to operate this unit.

A VE280 9cfm 2 Stage (BVVVE280) vacuum pump is recommended for this system.

Technical Specs:

Dimensions: 33” Width, 30” Depth, 81” Height

Weight: 270 lbs

Max Allowable Working Pressure: 150 PSI

Operating Temperature Range: -40F – 200F

304 Stainless Steel Construction

High Polish Interior

Solvent Capacity: 25 lbs

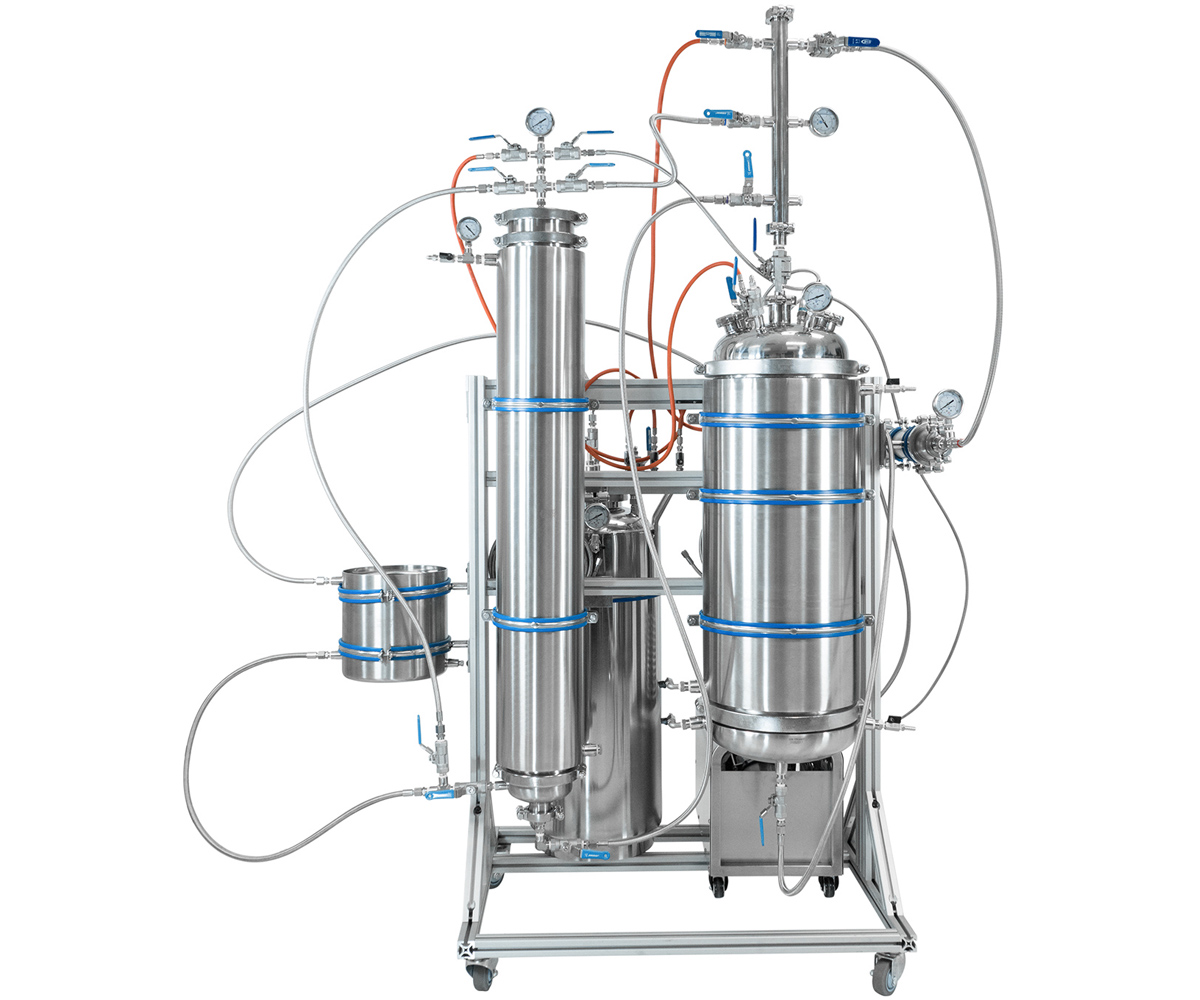

10 lb Mercurius Active Closed Loop Extractor

The Mercurius system is a rack-mounted MK-V that is specifically built to be run actively. Bi-directional solvent input prevents channeling and ensures a full yield is achieved. The Mercurius system also features a CMEP-OL recovery kit standard. The CMEP-OL has a coil bypass built onto the output to re-loop hot vapors back to the top of the material column. This is used to pressurize the material column after extraction to clear/assist in recovering the column. Hot vapor loop features a coil that can be heated in a warm water bath to boost vapor pressure/temperature.

The Mercurius system features a recovery manifold that is also used as the overflow path when bottom filling. This allows the column to be recovered independently from the collection base. With this plumbing, the user can utilize the evaporative cooling properties of the extraction solvents. By injecting a small amount of solvent into a closed material column, slightly wetting the material, then recovering this solvent, the material is frozen once all solvent flips phase. This method, paired with an injection coil, ensures efficient dewaxing happens without excessive dry ice or expensive chilling units.

This system is entirely rack mounted, giving this highly efficient system a small footprint.

Features:

• Up to 10 lb material capacity

• Bi-directional solvent input

• Injection coil dewaxing

• Vacuum insulated material column

• Recovery manifold for base and column

• Hot vapor reloop for column recovery

• Active recovery with CMEP-OL

• Rack mounted jacketed base for temperature control circulation

• Collection base drain port with extract dispensing wand

• Condensing coil for efficient recovery

• Sight glasses on collection base

• 100 micron filtration built into gasket

• Rack mounting

• Stainless steel recovery tank

• Molecular sieve to remove moisture from LPG

• ½” recovery lines

Benefits:

• Rack mounting to prevent heavy lifting

• Maximum oil yield

• Efficient dewaxing

• Save money with solvent reclamation

• Little to no solvent loss per run

• Limited dry ice consumption

• Fast run and recovery times

Includes:

• Extruded aluminum rack with pipe hangers

• 12” x 30” jacketed collection base with drain port

• #100 stainless steel jacketed LP tank with internal condensing coil

• Solvent injection chilling coil

• 6” x 48” material column

• CMEP-OL recovery kit

• Stainless steel braided PTFE hoses

• Buna-N tri-clamp gaskets

• High pressure clamps

ADDITIONAL EQUIPMENT REQUIRED FOR OPERATION OF UNIT. THIS UNIT REQUIRES A VACUUM PUMP, DRY ICE, NITROGEN TANK WITH REGULATOR, AND HEATER CIRCULATOR TO FUNCTION.

It is also recommended to have a refrigerant scale to operate this unit. A chiller can be run with the recovery tank to aid recovery times.

A Pro Series 21 cfm (BVVPS212B) vacuum pump is recommended for this system.

Technical Specs:

Max Allowable Working Pressure: 150 PSI

Operating Temperature Range: -40F – 200F

304 Stainless Steel Construction

High Polish Interior

Solvent Capacity: 50 lbs

8.5 lb Athena Bi-Directional Closed Loop Extractor

The 8.5 lb Bi-Directional rack has the same function as the stand alone bi-flow, but with the convenience of a rack mounting system. By using a bottom flood on the first wash to ensure all material has seen solvent, preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil bearing solvent is collected in the collection base under the material column. The Athena is equipped with a nitrogen assist to prevent solvent from getting hung up in the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent.

Features:

• Up to 8.5 lb Material Capacity

• Bi-Directional Solvent input

• Solvent Reclamation

• Sight glasses on collection base

• 100 micron Filtration built into gasket

• Rack Mounting

Benefits:

• Rack Mounting to prevent heavy lifting

• Maximum Oil Yield

• Save money with solvent reclamation

• Nitrogen Assist to prevent vapor lock

Includes:

• Extruded Aluminum rack with pipe hangers

• 12” x 48” Collection Base

• #100 LP Tank

• Solvent Input Manifold

• 6” x 36” Material Column

• Stainless Steel Braided PTFE hoses

• Buna-N Tri-clamp Gaskets

• High Pressure Clamps

ADDITIONAL EQUIPMENT REQUIRED FOR OPERATION OF UNIT. THIS UNIT REQUIRES A VACUUM PUMP AND NITROGEN TANK WITH REGULATOR TO FUNCTION.

It is also recommended to have a refrigerant scale to operate this unit.

A VE280 9cfm 2 Stage (BVVVE280) vacuum pump is recommended for this system.

Technical Specs:

Dimensions: 33” Width, 30” Depth, 71” Height

Weight: 229 lbs

Max Allowable Working Pressure: 150 PSI

Operating Temperature Range: -40F – 200F

304 Stainless Steel Construction

High Polish Interior

Solvent Capacity: 50 lbs

5 lb Mercurius Active Closed Loop Extractor

The Mercurius system is a rack-mounted MK-V that is specifically built to be run actively. Bi-directional solvent input prevents channeling and ensures a full yield is achieved. The Mercurius system also features a CMEP-OL recovery kit standard. The CMEP-OL has a coil bypass built onto the output to re-loop hot vapors back to the top of the material column. This is used to pressurize the material column after extraction to clear/assist in recovering the column.

The Mercurius system features a recovery manifold that is also used as the overflow path when bottom filling. This allows the column to be recovered independently from the collection base. With this plumbing, the user can utilize the evaporative cooling properties of the extraction solvents. By injecting a small amount of solvent into a closed material column, slightly wetting the material, then recovering this solvent, the material is frozen once all solvent flips phase. This method, paired with an injection coil, ensures efficient dewaxing happens without excessive dry ice or expensive chilling units.

This system is entirely rack mounted, giving this highly efficient system a small footprint. The rack also features a small shelf on the rear for tools and condensing coil.

Features:

• Up to 5 lb material capacity

• Bi-directional solvent input

• Injection coil dewaxing

• Vacuum insulated material columns

• Recovery manifold for base and column

• Hot vapor reloop for column recovery

• Active recovery with CMEP-OL

• Jacketed base for temperature control circulation

• Condensing coil for efficient recovery

• Sight glasses on collection base

• 100 micron filtration built into gasket

• Rack mounting

• Stainless steel recovery tank

• Molecular sieve to remove moisture from LPG

Benefits:

• Rack mounting to prevent heavy lifting

• Maximum oil yield

• Efficient dewaxing

• Save money with solvent reclamation

• Little to no solvent loss per run

• Limited dry ice consumption

• Fast run and recovery times

Includes:

• Extruded aluminum rack with pipe hangers

• 12” x 12” jacketed collection base

• #50 LP tank

• Solvent injection chilling coil

• 4” x 48” material column

• CMEP-OL recovery kit

• Stainless steel braided PTFE hoses

• Buna-N tri-clamp gaskets

• High pressure clamps

ADDITIONAL EQUIPMENT REQUIRED FOR OPERATION OF UNIT. THIS UNIT REQUIRES A VACUUM PUMP, DRY ICE, NITROGEN TANK WITH REGULATOR, AND HEATER CIRCULATOR TO FUNCTION.

It is also recommended to have a refrigerant scale to operate this unit.

A VE280 9cfm 2 Stage (BVVVE280) vacuum pump is recommended for this system.

Technical Specs:

Dimensions: 40” Width, 30” Depth, 100” Height

Weight: 464.25 lbs (including pump)

Max Allowable Working Pressure: 150 PSI

Operating Temperature Range: -40F – 200F

304 Stainless Steel Construction

High Polish Interior

Solvent Capacity: 25 lbs